Chapter 4. Tension and Compression (stress and strain)

Higher category : 【Materials Mechanics】 Materials Mechanics Table of Contents

1. Calculating Axial Stress

⑴ Tension, Compression

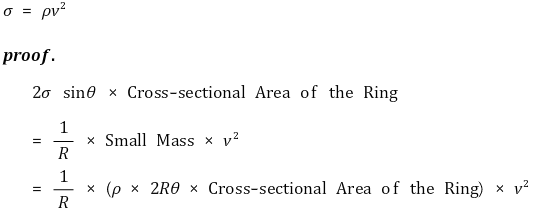

⑵ Tensile stress occurring in a thin ring rotating in a horizontal plane

2. Load-Deformation Curve(strain-stress curve)

⑴ Overview

① Load-Deformation Curve

○ X-axis : Strain

○ Y-axis : Stress

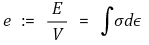

○ Area below : Energy

② Compression Testing Device

○ Load-Deformation curves are usually obtained through compression tests rather than tension tests

○ Universal Testing Machine (UTM) is typically used as the compression testing device

○ Hard samples : Set the descent speed of the crosshead to approximately 1.23 mm/min ± 50%

○ Soft samples : Set the descent speed of the crosshead to approximately 2.5-30 mm/min ± 50%

⑵ Elastic Region

① Definition : Range of deformation that can be restored by elasticity

② Proportional Limit

○ Definition : Range of deformation where Hooke’s law holds true

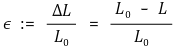

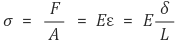

○ Hooke’s law : σ = Eε. σ : Stress. E : Elastic modulus. ε : Strain

○ Elastic Modulus (Young’s modulus, Modulus of elasticity)

○ It has a constant value from 0 to the proportional limit

○ The harder the object, the larger the E value, and the more difficult it is to deform

○ Apparent modulus of elasticity

○ Initial Tangent Modulus : Slope of the tangent at the origin

○ Secant Modulus : Average slope of the line passing through the origin

○ Tangent Modulus : Slope of the tangent at any point

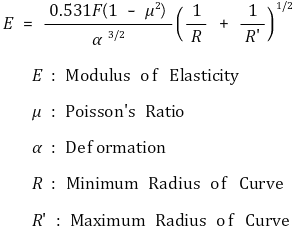

○ Formula of elastic modulus derived from Hertz’s contact theory

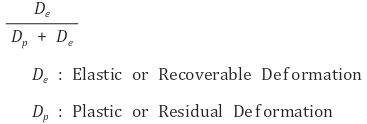

○ Degree of Elasticity

○ Resilience : Area under the stress-strain curve up to the proportional limit. One of the measures of deformation energy

○ If the proportional limit is not defined, it is sometimes defined as the area up to the yield point

○ Example:

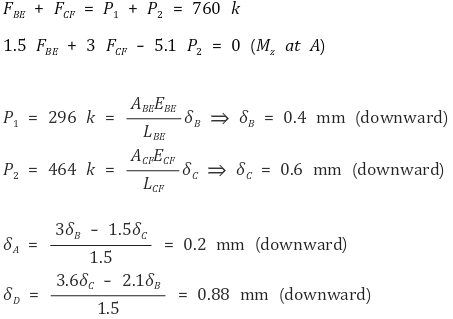

○ The horizontal rigid beam ABCD is supported by vertical bars BE and CF and is loaded by vertical forces P1 = 400 kN and P2 = 360 kN acting at points A and D, respectively (see figure). Bars BE and CF are made of steel (E = 200 GPa) and have cross-sectional areas of BE = 11,100 mm² and CF = 9,280 mm². The distance between various points on the bars are shown in the figure. Determine the vertical displacements δA and δD of points A and D, respectively.

③ Yield point

○ End of the elastic region: After the yield point, micro-damage begins and the material cannot return to its original state.

○ Point where the load does not increase temporarily.

○ Roughness : Energy required until the yield point.

○ Stiffness : Average slope from 0 to the yield point.

○ Yield deformation: Deformation from 0 to the yield point.

④ Hysteresis

○ Hysteresis: Phenomenon where the physical quantities of a material are determined not only by its current state but also by the process of state change.

○ Hysteresis of the stress-strain curve: Phenomenon where deformations beyond the yield point do not recover to the original state even after the load is removed.

○ Mechanical hysteresis: Amount of energy absorbed during loading and released during unloading.

○ Mechanical hysteresis is represented by the amount of work per unit volume in J/m³.

○ Hysteresis loss: Ratio of the mechanical hysteresis to the absorbed energy during loading, expressed as a percentage.

⑶ Plastic region

① Definition: Range of deformations that cannot be restored by elasticity.

② Elastic and inelastic strain energy

○ Within the elastic limit: Total energy is restored.

○ Beyond the elastic limit: Only the energy related to the new elastic range is restored.

③ Rupture or fracture

○ Definition : Point at which an object is completely destroyed.

○ Toughness : Energy required until the final rupture point.

○ Rupture of deformation: Deformation from 0 to the final rupture point.

○ Fracture strength: Stress applied to the material at the moment of rupture.

④ Ultimate stress: Maximum stress between the yield point and the final rupture point.

○ Generally refers to the stress at the final rupture point.

○ Strength: Ultimate stress of an object.

⑤ Ductility and brittleness: Degree of difference

○ Ductility: Property that requires a significant amount of deformation from the yield point to the final rupture point.

○ Ductile materials undergo significant deformation along the fracture surface.

○ Brittleness: Property that requires a small amount of deformation from the yield point to the final rupture point.

○ Brittle materials undergo minimal deformation along the fracture surface.

⑷ Fatigue

① Definition: Phenomenon where a material is destroyed after a certain period of time, even when subjected to stresses below the fracture stress.

② Cyclic fatigue

③ Materials with viscoelasticity have stress-load relationships that change over time.

○ Explained by the rheological model.

○ Stress relaxation : Phenomenon where stress decreases when strain remains constant.

○ Creep phenomenon : Phenomenon where damage occurs even under small loads below the yield point if the duration of loading is long.

⑸ Poisson’s ratio

① Definition: Ratio of lateral strain to longitudinal strain.

○ Poisson’s ratio is always positive.

○ Value depends on the crystal structure.

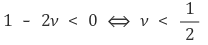

○ Poisson’s ratio is always less than 0.5.

○ For metals, it is generally around 1/3.

② Change in cross-sectional area: In terms of Poisson’s ratio ν,

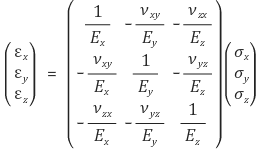

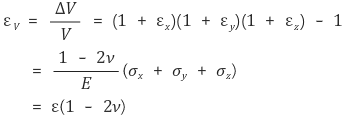

③ Change in volume: Obtained through the principle of superposition.

○ Formulation

○ It is possible to determine the volumetric strain εV by extending the crystal structure of a specific cross-section.

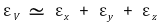

○ Volumetric strain εV can also be expressed approximately as:

○ Volume cannot have a negative change when subjected to expansion.

○ However, rubber has a Poisson’s ratio ν of 0.5, so there is no change in volume.

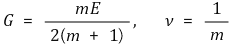

④ Relationship between longitudinal elastic modulus E and shear modulus G

3. Various stresses

⑴ Eccentrically loaded single bar

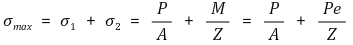

① Maximum stress: Note that M represents the moment about the center of gravity.

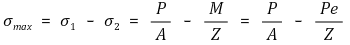

② Minimum stress: Note that M represents the moment about the center of gravity.

③ Eccentricity: The eccentricity e is the distance where the minimum stress becomes 0.

⑵ Column

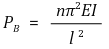

① Euler’s buckling load: Also known as the critical load or the safe load.

○ n: End-fixity coefficient. A higher value indicates a stronger column.

○ ℓ: Length of the column. A longer length indicates a weaker column.

○ Note: EI is often attached.

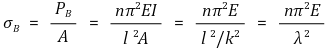

② Euler’s buckling stress:

○ k: Radius of gyration (2nd moment of area of the minimum cross-section)

○ λ: Slenderness ratio

③ Slenderness ratio: Also known as the effective slenderness ratio.

⑶ Thermal stress

① Thermal expansion: When the temperature of a component increases, its length increases in all directions due to increased kinetic energy.

○ Linear expansion coefficient α and temperature change ΔT: Length ℓ = ℓ0 (1 + α ΔT) for a linear object.

○ Volumetric expansion coefficient β and temperature change ΔT: Total volume V = V0 (1 + β ΔT) for an object.

○ β ≒ 3α holds approximately: 1 + β ΔT = (1 + α ΔT)3 ≒ 1 + 3α ΔT (proof)

○ Thermal expansion coefficient: Zn, Pb, Mg > W, Mo > V

② Thermal stress: Stress that occurs when a component undergoes thermal expansion but the distance between two points cannot change.

⑷ Impulse stress

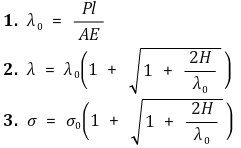

① Formulation: Note: Memorization is required.

② When the force is applied suddenly without initial velocity, σ = 2σ0: Substitute H = 0 into the equation.

⑸ Indeterminate

① Example

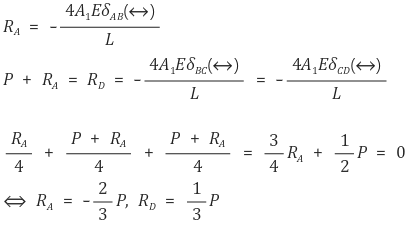

○ The axially loaded bar ABCD shown in the figure is held between rigid supports. The bar has a cross-sectional area A1 from A to C and 2A1 from C to D. Determine the reactions RA and RD at the ends of the bar.

Input: 2016.04.24 16:32

Revised: 2020.06.30 21:33